Solutions

JMK smart customization

We customization process offers our clients a one-stop service from design to production. We design and manufacture unique products based on client needs, meeting their specific requirements.

Our OEM/ODM service simplifies the journey of turning your ideas into reality. We prioritize tailoring products to your specific requirements, guaranteeing that you receive optimal solutions with minimal hassle.

Contact Us- Product appearance design

- Reasonable product structure

- Professional mold design

- Product packaging design

OEM/ODM service

Our OEM/ODM service simplifies the journey of turning your ideas into reality. We prioritize tailoring products to your specific requirements, guaranteeing that you receive optimal solutions with minimal hassle.

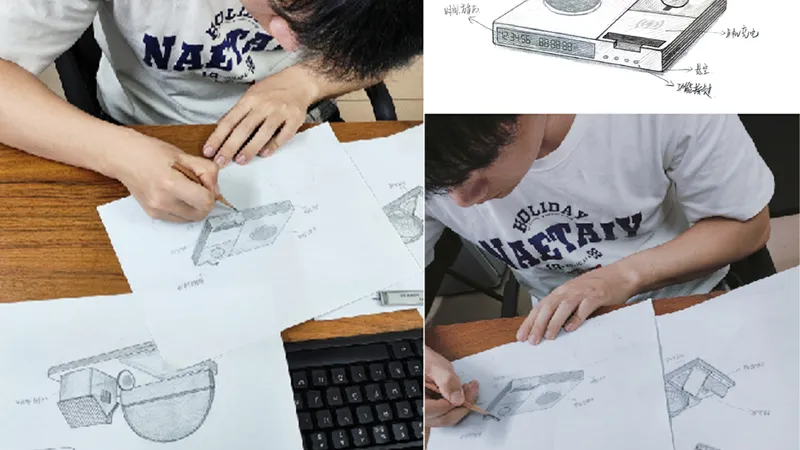

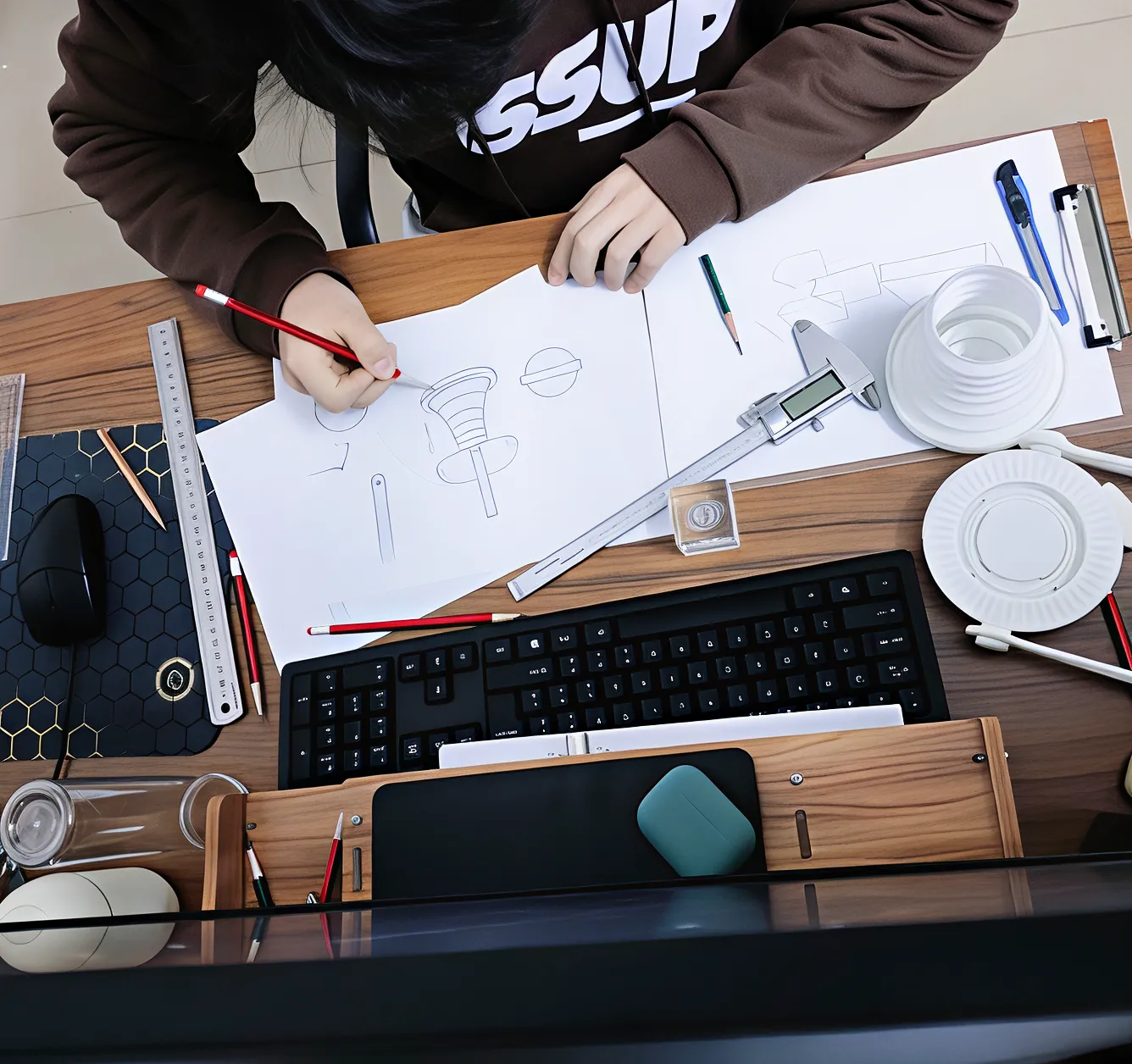

Product appearance design

When we start product design, We JMK Smart's design department will start brainstorming. Draw 10 grass drawing paper first, and then, we will choose one of the 10 drawings for the next structural design. To ensure that every work is brought to the market and deeply loved by users.

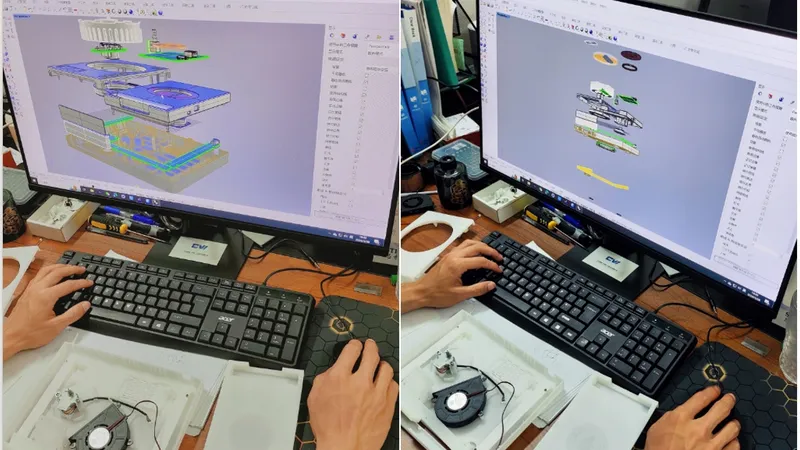

Reasonable product structure

Reduce the manufacturing cost of products, improve production efficiency, provide reliable performance guarantee, and make products more competitive.

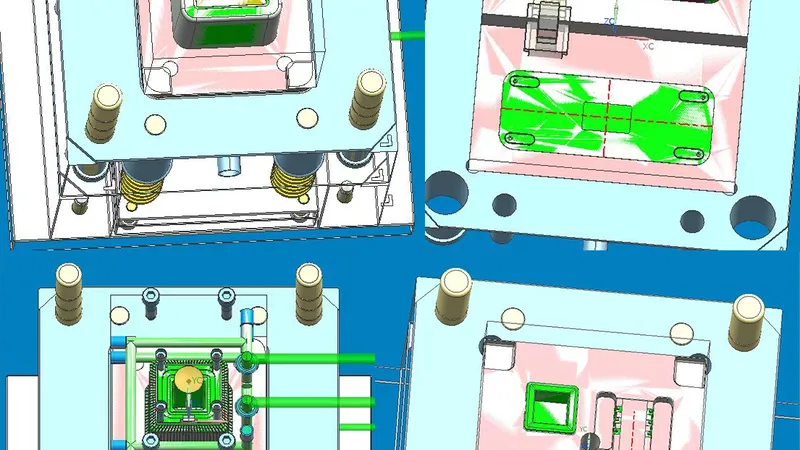

Professional mold design

Accuracy of mold making, reducing unnecessary mold expenses and helping products to go to market quickly.

Product package design

According to your packaging style positioning and color requirements, we help you design the internal and external packaging of your products.

Customization process

We have always adhered to the principle of providing high-quality, high-performance products to our customers. Our products feature unique and fashionable designs while also emphasizing simplicity and portability, bringing more comfort and convenience to users' lives.

Project review meeting

After completed the first T0 trial production, all the problems found will be reviewed one-on-one. Electronic engineers and structural engineers will participate in improving and solving the problems together.

Intentional payment signing agreement

The intentional payment phase requires clients to pay a deposit after confirming the customization requirements and preliminary design scheme, to initiate the subsequent design and production processes.Sign an agreement.

Drawing design

The drawing design phase involves our designers creating detailed design drawings based on client needs and early-stage analysis, including the product's appearance, structure, and functionality.

JMK Smart's Injection molding center

Our company has a total of 52 brand injection molding machines, mainly producing precision products such as plastic parts of consumer electronic products, hardware tools, medical equipment, etc. The annual production of injection molding has accumulated more than 10 million beers, and there are several injection molding machine adjustment masters with more than 13 years' experience.

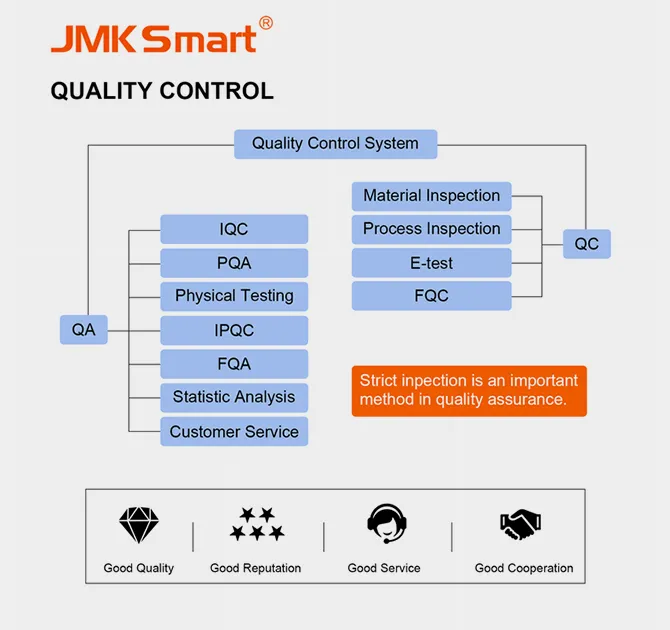

Production process management & quality control

Production process management refers to a series of production processes and procedures needed to complete the product, which is an indispensable part of the production process. Doing a good job in production process management can effectively control and reduce mistakes and waste in the production process, improve production efficiency and quality, and ensure the stable and sustainable development of product quality. Reasonable process flow, scientific process parameter setting, taking into account various risks and adverse factors, preventing bottlenecks, and constantly improving and improving.

Ensure the quality of each batch of goods is qualified and delivered on time.

Full Container flow (FCL):

Customer orders → production and stocking → space booking → container loading → customs declaration → shipment → bill of lading → customs clearance → customer receipt.

1. Order confirmation and stocking

2. Booking the shipping space

3. Loading

4. Customs declaration and documents

5. Shipping and tracking

6. Customs clearance and delivery at the port of destination

Inside the factory

With a better understanding of the market and customers in the American and European region, our talented and creative design team will work alongside you to achieve business success.